Insulated glazing, more commonly known as double glazing (or double-pane, and increasingly triple glazing/pane) are double or triple glass window panes separated by an air or other gas filled space to reduce heat transfer across a part of the building envelope.

Insulated Glass Units are manufactured with glass in range of thickness from 3 mm to 10 mm (1/8″ to 3/8″). Laminated or tempered glass may also be used as part of the construction. Most units are manufactured with the same thickness of glass used on both panes but special applications such as acoustic attenuation or security may require wide ranges of thicknesses to be incorporated in the same unit.

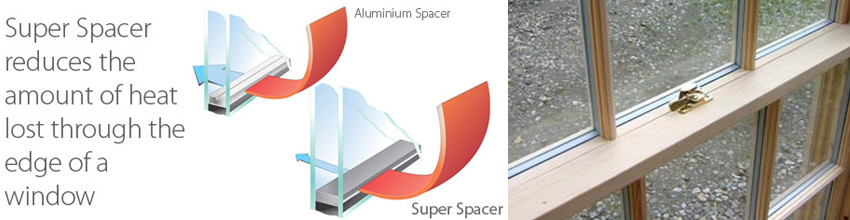

The glass panes are separated by a “spacer”. A spacer is the piece that separates the two panes of glass in an insulating glass system, and seals the gas space between them. Historically, spacers were made primarily of metal and fiber, which manufacturers thought provided more durability.

Double Glazed Windows are manufactured on a made to order basis. The width and height dimensions, the thickness of the glass panes and the type of glass for each pane as well as the overall thickness of the unit must be supplied. On the assembly line, spacers of specific thicknesses are cut and assembled into the required overall width and height dimensions and filled with desiccant. On a parallel line, glass panes are cut to size and washed to be optically clear.

An adhesive sealant is applied to the face of the spacer on each side and the panes pressed against the spacer. If the unit is gas filled, two holes are drilled into the spacer of the assembled unit, lines are attached to draw out the air out of the space and replacing it with the desired gas. The lines are then removed and holes sealed to contain the gas. The more modern technique is to use an online gas filler, which eliminates the need to drill holes in the spacer. The units are then sealed on the edge side using either polysulfide or silicone sealant or similar material to prevent humid outside air from entering the unit. The desiccant will remove traces of humidity from the air space so that no water appears on the inside faces (no condensation) of the glass panes facing the air space during cold weather. Some manufacturers have developed specific processes that combine the spacer and desiccant into a single step application system.

The double glazed window was invented in 1930s. After so many decades, the manufacturing process is well established, though innovation has continued to improve the R factor and other characteristics of windows.

Materials which can be used for double glazing include aluminum, PVC, and wood (timber).

1047 Howitt Street Wendouree

Vic 3355 Australia